People are using gravure printing or Intaglio printing for high-quality printing techniques that are used for getting high quality images with high resolution. The gravure printing cylinders, which are important to the process precision, are the primary component of this approach. To obtain an in-depth understanding of the primary features of engraving on a gravure printing cylinder and the gravure cylinder itself https://www.laserengravingmanufacturers.com/gravure-printing-cylinder-engraving/ visit here.

High Precision and Detail

This process of gravure printing cylinder engraving is very precise. This process involves cutting small cells or depressions and every detail on the surface of the cylinder. These cells contain different levels of ink and can reproduce very fine details and gradations of tone.

Variability of Depth and Cell Size

The people working with these printing cylinders can manually adjust the depth and size of the cells. The depth of the cells determines the amount of ink that is transferred while the size of the cells determines the resolution of the printed image.

Use of Different Materials

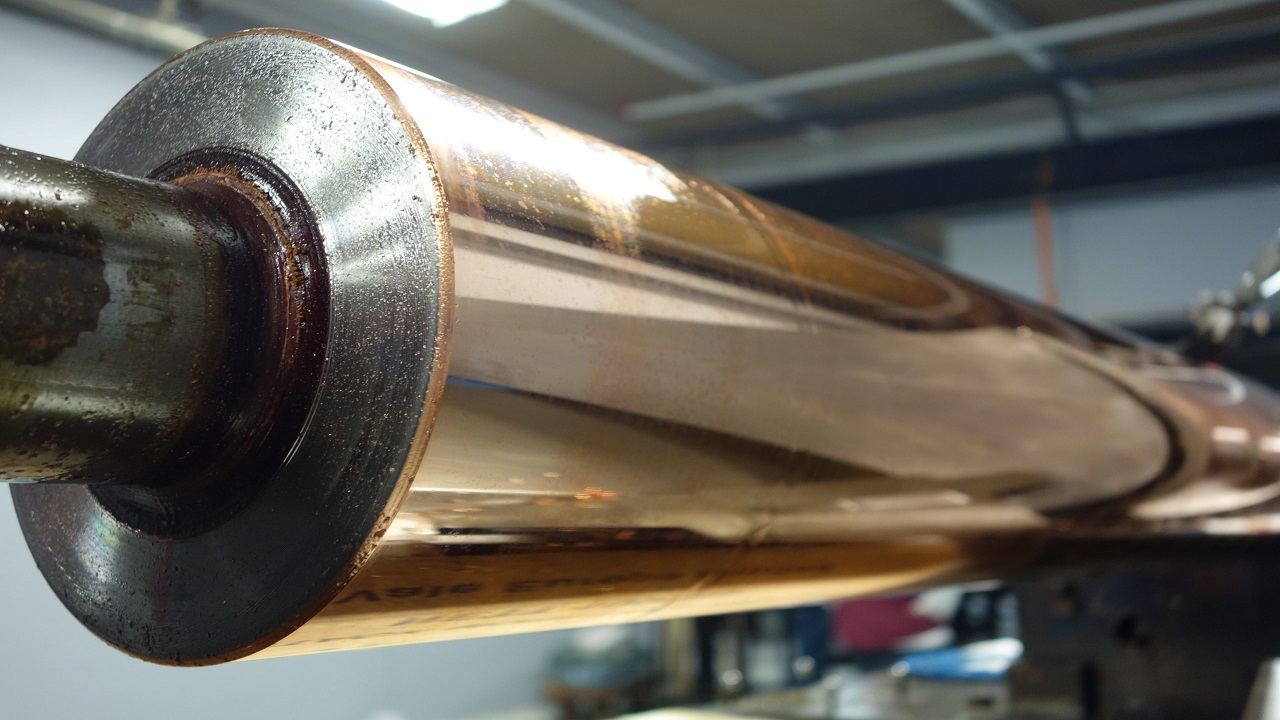

People should know the kind of printing cylinder that is compatible with the needs of the organization. Many materials like copper, steel, or even photopolymer or rubber are available in the market. Copper cylinders are preferred due to their high ink transfer characteristics and long lifespan. The type of material affects the engraving process and the quality of the print that is produced.

Automation and Efficiency

In this modern world engraving of printing cylinders is more automated due to the development of electronic and laser engraving. Computerized systems help in engraving, minimize errors, and increase productivity. This automation is especially useful in mass production since it is essential to produce a high number of items in a short period and with consistent quality.

Characteristics of Gravure Cylinders

Durability and Longevity

Gravure cylinders are made to be long-wearing and are projected for multiple uses. The materials used, copper or steel, are selected based on their durability in the process of printing. This durability makes gravure cylinders ideal for high-volume production where the cylinders can go through many cycles of use without much erosion.

Consistency and Uniformity

The most important characteristic of gravure printing is the stability of the print quality. The gravure cylinder has a flat surface hence making it possible to produce prints that are like the previous ones. This uniformity is important for applications where color matching is critical and fine details are important.

Cost-Effectiveness

While the initial investment for gravure printing such as cylinder engraving is expensive, the cost per print is low for large volumes. The quality of the prints produced in gravure printing is high and the quality is maintained throughout the long production runs which makes gravure printing the most preferred method for mass production.

Conclusion

Gravure printing cylinder engraving and the gravure cylinders are focal to high quality printing in the world. These characteristics from precision and material versatility to durability and efficiency explain why gravure printing is a technique for creating detailed and uniform prints. Knowledge of these characteristics is useful in comprehending the value and versatility of this complicated printing method.